What is Dye-Sublimation?

Dye-Sublimation is a printing technology which “Dyes” polyester fabric by transforming the inks into a heat-activated gas which bonds with the “Fibers”. This results in a brilliant finish with a wide photographic gamut.

Dye-Sublimation is a printing technology which “Dyes” polyester fabric by transforming the inks into a heat-activated gas which bonds with the “Fibers”. This results in a brilliant finish with a wide photographic gamut.

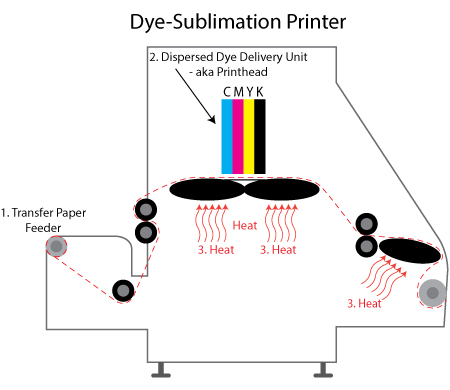

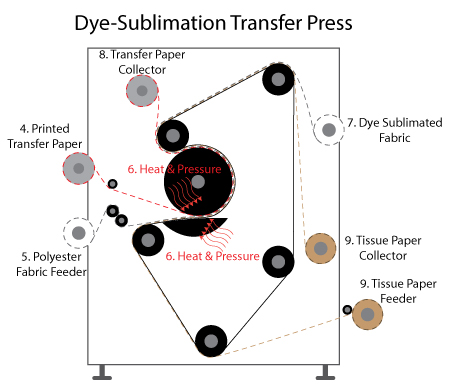

The actual process involves printing a digital file on special paper, using large format printers, and then heat-pressing the images to fabric using a large format rotary heat press.

The end result is remarkable! Brilliant full-process color, from simple to highly complex designs, printed on several standard polyester fabrics.

Printed on a special transfer paper, Dye-Sublimation inks turn into a gas when heated to around 425 degrees. Through heat and pressure the ink forms a bond with the “Fibers” and “Dyes” the fabric. At this point the product is foldable, washable and ready to be finished.

Dye-Sublimation Inks are called “Dispersed Dyes” designed to work with 100% polyester fabrics.

Presses vary in sizes capable of producing images 10′ wide without a seam. If larger prints are needed they can be produced in tiles and sewn back together with a “T-Shirt” seam. This type of seam is very small and hides well in large banners.

Most any indoor graphics can be produced with this process. Everything from trade show displays and media backdrops to event/stage graphics, custom flags and more.

Most direct printing has to be done on fabrics coated for direct print, this assures the image doesn’t bleed while printing. This coating produces a barrier between the fabric and ink. Before you have even started the job, your fabric will have memory for wrinkles and feel crunchy to the touch. Once you print to coated fabrics your ink sits on the surface of the fabric adding another layer to the fabric. This again increases the crunchy feeling of the fabric and causes the material to have more memory for wrinkles.

It doesn’t. No richness to colors. No bonding to the fabric itself.